When it comes to prototype casting fine sand is by far the most popular material to use in the process from dsfsdf's blog

The team here at diecasting-mould is highly skilled in the field of prototyping, and we regularly produce prototypes and models for our clients. There are a variety of approaches that we can use to achieve our goal, which we will discuss further down in this section. Sand casting is one of the most commonly used methods of producing prototypes at XYZ Manufacturing, and it is also one of the most expensive methods of producing prototypes. Sand casting is one of the most commonly used methods of producing prototypes at XYZ Manufacturing. Sand casting is one of the most commonly used methods of producing prototypes at XYZ Manufacturing, and it is also one of the most cost effective. Whatever your needs are, no matter how complex they are, our experts can assist you with them: whether you want to eliminate product design flaws before investing in machining, or whether you want to produce anywhere from one to five hundred thousand castings per year with the help of our experts.

However, due to the large number of popular YouTube videos that have gone viral and are now being shared on social media, it can be difficult to comprehend the process. Some of you may be completely unaware of the fact that there are three different types of sand that are used in sand casting operations. This is something that many people are unaware of. One of the most important components of this process is determining the best time to use each type of sand, as well as the reasons for using each type of sand in specific situations, and this is one of the most time-consuming components.

As previously stated, there are three different types of sand that can be used in the casting process. This blog post will explain why each type of sand is used, as well as the different applications for which each type of sand is used.

Indeed, there are several questions to consider, including what exactly is sand casting and how it operates. Continue reading to learn more about what it entails.

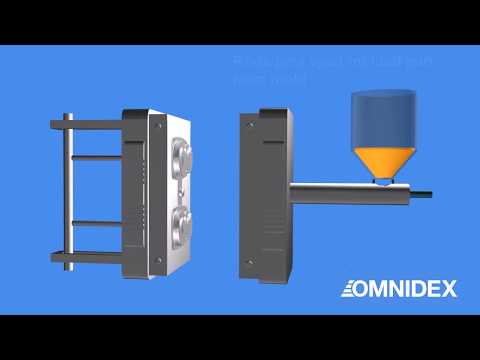

Creating non-ferrous metal casts is made possible through the use of sand mold casting, which is a type of non-ferrous metal casting technique. Sand mold casting is a non-ferrous metal casting technique that is commonly used in the automotive industry for the production of non-ferrous metal casts. An extremely high-temperature environment is used to melt the metals to the point where they become liquid, after which the liquid metals are poured into an empty sand mold that has been prepared in advance so that they can harden and become permanently set. Contrary to popular belief, despite the appearance that it is a relatively new technique in nature, this is not the case. In light of the fact that sand China die casting mold has been around for nearly 6,000 years and has only undergone a few minor refinements during that time period, this is an impressive accomplishment, especially considering that it is an extremely technical procedure.

Some people enjoy sand casting as a recreational activity, but at Protocast Inc., we provide professional die casting China and prototype manufacturing services to businesses that require precision-made casts to be produced in a professional setting. We also provide professional China die casting manufacturer and prototype manufacturing services to businesses that require precision-made casts to be produced in a professional setting. Our professional casting and prototype manufacturing services are also available to businesses that require precision-made casts to be produced in a professional environment. Business customers who require precision-made casts to be produced in a professional environment can take advantage of our professional die casting defects causes and solutions and prototype manufacturing services. Get in touch with us if you have any questions or would like to learn more about our products or services.

It is necessary to use three different types of sand when zinc castings in sand, despite the fact that it is a relatively simple process.

A greenish tint has been added to the sand as a result of the coloring process.

Clay sand is a type of sand that is compacted in a mold after being placed in the mold and allowed to dry while the mold is being packed down; this type of sand is also known as wet sand. Clay sand is compacted in a mold after being placed in the mold and allowed to dry while the mold is being packed down. The fact that it is still in its uncured state when the metal is poured into it while it is still green gives green sand a distinct advantage over other types of sand when used in the aluminum alloy die casting process. The fact that green sand can be recycled, as previously stated, plays a role in this. Because of its ability to be recycled, it is a more cost-effective option for sand casting than other sand casting materials.

While wet sand is a cost-effective material to use, it is unsuitable for this application due to its unstable nature, which has the potential to shift or collapse during the casting process. This is despite the fact that it is an extremely inexpensive material to use. This sand aluminum die casting method is considered to be a viable method of prototyping that will not be phased out in the near future due to the cost-effectiveness of this method outweighing the risk of cast shifting.

Some people refer to this type of sand as Water Glass Sand, which is a more formal term. Sodium Silicate Sand is a type of sand that is primarily composed of sodium silicate. It is used in the construction industry. In the construction industry, it is widely used. When it comes to the construction industry, it is extremely popular.

Sodium silicate is another chemical compound that is frequently used in the production of castings. It is a compound that is found in a variety of applications. There are numerous applications for this chemical compound, which can be found in a variety of settings. After being exposed to carbon dioxide for a few seconds, sodium silicate transforms from a liquid to a solid that cannot be moved. This substance is distinct from other substances due to the fact that it has a one-of-a-kind composition when compared to other substances. As previously stated, one of the most significant advantages of using sodium silicate casting for cavity casting projects is that the material is particularly well suited for such applications, which is a significant advantage. Another advantage is that the material is relatively inexpensive. Furthermore, the material is relatively inexpensive, which is another plus.

It is not necessary to use other materials in order to ensure that the cast can be broken down and the core extracted because sodium silicate is a very durable material. If the materials are not properly combined, an incorrect material combination may result in the cast becoming ineffective and even useless.

Specifically, resin sand is defined as any sand that is predominantly composed of resin-based materials and is used in the construction industry for the purposes of this article.

Because of the melting of the resin during the heating process, the finished product has a smooth surface finish due to the solidification of the resin as a result of the heating process. It is not necessary to use resin sand in the production of castings, but it can be beneficial in the production of a finished cast surface that is flawless and free of imperfections, which is critical when it comes to the production of finished castings. The manufacturing of resin sand is well-known for being significantly more expensive as well as time consuming when compared to the production of green sand and sodium silicate. However, resin sand produces the highest-quality casts when compared to any of the other available materials. For their part, green sand and sodium silicate are well-known for being significantly more expensive and time-consuming than resin sand. This is true both in terms of the costs involved as well as the amount of time required to complete the manufacturing process. Molds made of silicate sand are the most widely used type of mold in the industry for applications in which the cast quality must be absolutely flawless, such as in the aerospace and defense industries. In addition, they are the most expensive. They are also the most expensive of the available alternatives.

The Wall