dupliauuukjena's blog

Because flat-welded flange connections have higher tensile, compression, torsion, and shear strength requirements than other types of connections, they may be used in applications where these characteristics are required. In this situation, large flanges are a better choice than small ones.

Some of the products offered by the company include stainless steel flanges, flat welding flanges, welding flanges, ring flange covers (blind flanges), small diameter flanges, and high-pressure ASME Flange finishing.

The flat welding threaded pipe flange connection device is used to connect two large diameter pipelines in the United States. The flat welding flange connection device is used to connect two large diameter pipelines in the United States. Two socket weld pipe flanges pieces and several fastening bolts are typically used in the construction of this structure. In its raw state, low carbon steel has a high degree of plasticity and low strength, but after a sufficient amount of the carbon element has been added to it, it will harden. As a result of its decreased plasticity and increased strength, this type of material is typically used for pipeline construction. It is possible to rotate the pipes in this situation by loosening the bolts on both sides of the pipes, after which the pipes can be easily disassembled and reassembled by tightening the bolts.

The majority of the time, flat welding flanges are used to join the pipes together. By retightening the bolts on both sides, the pipes on both sides can be rotated, and the pipes can be disassembled and reassembled in a short period of time by rotating the pipes and tightening the bolts on both sides again. Carbon steel flanges are a type of Custom Engineered Flanges that is made of carbon steel; the connection method of flat welding flanges is the most straightforward and cost-effective connection method for cast iron pipes and steel pipes.

When the inspection port is not in use, the blind plate can be used to open the inspection port and prevent it from being closed. The China Top Grade Blind Flange connection can be used to connect pipes with diameters ranging from 50mm to 315mm, depending on the manufacturer. Non-rigid connection, disassembly and assembly, and tensile strength are all characteristics of the matching flange. Detachable connectors, such as those used in power transmission, are commonly used in this manner of connection on low-pressure transmission pipelines, which are common in the industry.

Welding flanges are available in a variety of configurations, including threaded (threaded connection) and flat. Low pressure is handled by high pressure low pressure small diameter threaded flanges, whereas high pressure low pressure large diameter welding flanges are employed for high pressure low pressure large diameter. When different pressures are applied to the flange, the thickness of the flange changes, as does the diameter and number of connecting bolts.

Working in the metal fabrication industry is extremely dangerous work, regardless of which specific field you choose to specialize in. Whether it's handling raw materials or operating machinery, this holds true in every situation.

It is possible to have an arm, a hand, or a finger taken away from you in a matter of seconds. It is possible that you will die as a result of your failure to adhere to proper safety procedures if you do not follow them. Performing this trade correctly can be extremely rewarding in a variety of ways, but performing it incorrectly can completely devastate one's own life or the lives of those around them.

What Characteristics Do You Require to Be Successful?

Prior to anything else, determine which group and subgroup(s) most interests you and devote all of your time, energy, and resources to that group and subgroup(s). It is critical to continue learning about it at all times.Quality control is a component of quality management.

Afterwards, put your newly acquired knowledge to good use by completing the following tasks. Is working as an engineer in a fabrication shop something you've always dreamed of doing? In order to improve the overall quality of your product design, it is necessary to learn about the process and get your hands dirty. You may prefer to work with your hands rather than a computer if this is your preference. Make a bold move forward! There is no field or subgroup that is either more or less important than the others in terms of importance or importance in comparison to the others. The ability to perform each of these tasks requires a distinct set of skills. There is no sense of embarrassment in this work, only awe and admiration for what has been accomplished.

The fact that you are a professional fabricator for someone who is similar to you may inspire you to begin teaching once you have established yourself as an authority in your field. It is without a doubt that as time progresses, you will be able to pass on your knowledge to those who are in your immediate vicinity. However, even though it is possible to go even further in your career, you may wish to consider teaching at a trade school or even publishing a book.

Teaching students the ability to demonstrate their pride in what they do and the products they are capable of producing is extremely beneficial. Your ability to demonstrate to others that they, too, can follow in your footsteps, just as you are doing so in the footsteps of your grandfather, will be greatly appreciated, and they will be extremely grateful to you for doing so.

Possibilities for the Future Look Good

It is difficult to determine the exact requirements for being a successful professional fabricator in this or any other trade, but once you have decided on a path, give it everything you have.

Further consider that you may decide at some point that the activity you have chosen is not for you, and that is perfectly acceptable. Regardless of how you choose to enter the workforce, much of what you have learned will be transferable and will even help you become a more effective professional in your chosen field.

Greetings and best wishes on your decision to pursue a career in the manufacturing industry. You made a wise decision in this matter. I wish you and everyone else the best of luck in your endeavor, and I wish you and everyone else the same. Everyone has a bright and interesting future ahead of them, and they should be optimistic about it.

The type of metal alloy to be used in die casting may not always be a straightforward decision, however, and this is a possibility. Informed decisions about which type of die cast material will be most suitable for your requirements can then be made based on this knowledge base.

Several characteristics distinguish die cast aluminum from other types of aluminum.

Despite the fact thataluminum die castings did not become the most widely used die cast alloy by chance, it worked extremely hard to achieve this position. Even though aluminum die casting is not always the best option, the properties of aluminum die casting make aluminum die casting parts a popular choice among designers and engineers for a wide range of applications. Several characteristics of aluminum, when used in die casting processes, are shown in the following table.

It's a small and lightweight piece of equipment.

It has an extremely high melting point and is extremely strong.

It possesses exceptional thermal and electrical conductivity characteristics.

It is a material that can be recycled.

It does not have any magnetic properties.

In addition to aluminum's inherent properties (such as its strength and recyclable nature), other metal alloys have similar characteristics. On top of all that, aluminum is unique in thataluminum die casting parts is cast using a cold chamber method rather than a hot chamber method, which makes aluminum die castings particularly durable. Due to the fact that it has a higher melting point, it is more flammable.

There are numerous advantages to working with aluminum die cast manufacturers.

You will not gain any additional weight as a result of the following:In addition to not adding any additional weight to your machinery or equipment, one of the most significant advantages of using aluminum die cast components is that they are extremely light in weight. Components made of aluminum are typically used in the automotive and aerospace industries when it is necessary to ensure that the design of the component does not impair the component's speed or balance.

You won't have to worry about aluminum parts losing their structural integrity in high temperatures or harsh environments because of the high melting point and high levels of durability that aluminum possesses. As a result, it can be relied upon in virtually any situation.

Because of aluminum's versatility, it can be used in a wide range of applications, from components with a beautiful finish to components with ultra-thin wall thicknesses. Moreover, it is a good match for virtually any industry. In addition to those working in the information technology sector, aluminum die casting is an excellent choice for companies that specialize in technological device manufacturing, as well as businesses that want to emphasize environmentally friendly practices, among other things.

You may discover that zinc die casting or other types of alloys will be more beneficial to your company's bottom line in some cases, but this is not always the case. Any of you who are unsure about which type of die cast alloy will best meet your needs can contact us and we will be happy to guide your decision-making process and provide you with the information you need to make an informed decision. Please get in touch with us right away if you want to learn more.

In spite of the fact that ceramic tiles have been used as part of the home furnishing industry for a very long time, they are still extremely popular in today's market, despite the fact that they have been around for such a long period of time. Our ultimate goal today is to transport you to the building in question so that you can hear what people have to say about the marble tiles that cover the entire exterior of the building. We hope you enjoy your journey today. Is it accurate to say that the marble tiles that cover your entire body are a true reflection of your personality? Is this true? Do you think they're telling the truth?

A significant advantage is the ease with which it can be used, and this is an important advantage.

There are currently two different sizes and shapes of full-body marble tiles available for purchase on the market: square and rectangle, both of which are available for purchase on the market. You can choose from two different color options: white or black, to make it even more convenient for yourself. Based on their size and shape, there are currently two different configurations of square and rectangular full body marble tiles available on the market, which are designated as square and rectangular, respectively. In addition to square sizes ranging from 600*600 to 800*800, rectangle sizes ranging from 600*600 to 800*800, 900*900 to 1000*1000, and other options, rectangle sizes ranging from 600*600 to 800*800, and other options, are available. The rectangle sizes 600600 to 800800 and other options are also available. Rectangle sizes 600600 to 800800 and other options are also available, as are rectangle sizes ranging from 600600 to 800800 and other options. Despite the ceramic tiles manufacturers fact that 800*800 resolution is the most widely available resolution on the market, China exports more images with 900*900 resolution than any other country in the world, according to the International Trade Administration. Because of this, it is critical that the stripe's width and height be as long as possible in both width and height, in order to ensure that the stripe has the greatest amount of effectiveness. Create images with a variety of resolutions, such as 450 x 900 pixels, 600 x 1200 pixels, 900 x 1800 pixels and so on. Based on their prevalence in different parts of America, the first is more prevalent in the southern United States, whereas the latter two are more prevalent in parts of northern America and the first is more prevalent in parts of southern America.

Especially important in terms of the overall process are the stages of planning and preparation that take place beforehand.

It is important to us that we demonstrate our commitment to environmental protection.

The installation of whole-body marble tiles has been completed in order to compensate for the increasing scarcity of natural stones on the market. The installation of whole-body marble tiles has been completed in order to compensate for the increasing scarcity of natural stones on the market. In traditional construction practices, it is common for natural soil and stone to be calcined at high temperatures before being used in construction projects, such as building foundations. However, despite the lengthy duration of the process, the hazardous gas is removed from the environment before the process is completed. Thus, the general public now perceives this particular type of ceramic tile as more environmentally friendly than other types of ceramic tile as a result of these developments. Despite the fact that we are in serious danger, it does not appear to bother us that we are putting ourselves in such a dangerous situation.

When using this mode of communication, there are several drawbacks, the most significant of which are as follows:

It is essential for players to understand how to select appropriate tiles and to have the necessary abilities in order to win the game.

Ceramic tile products are divided into five categories: superior products, first-class products, second-class products, third-class products, and low-quality or substandard materials. Superior products are distinguished from first-class products, which are distinguished from second-class products. Superior products are distinguished from first-class products by the superior quality of their materials and the first-class presentation of their packaging. Superior quality products can be distinguished from products of first-class quality, which can then be distinguished from products of first-class quality, which can then be distinguished from products of first-class quality, and so on. In that order, superior goods are distinguished from first-class goods are distinguished first, followed by superior goods being distinguished from second-class goods, and so on. It is possible to tell the difference between inferior and superior products when comparing them side by side. Third-class products are distinguished from first- and second-class products, and substandard products are distinguished from inferior products. Third-class products are distinguished from inferior products. Products classified as third-class are distinguished from inferior products. Third-class products are distinguished floor tiles wholesale from inferior products by the classification system. Through the use of a classification system, superior and inferior products are distinguished from first- and second-class products, respectively. Superior products must first be identified and then distinguished from inferior products, as described in the preceding section, before superior products can be distinguished from inferior products. A thorough comparison between them is required due to the significant price disparity between them. In order to ensure that the kitchen wall tiles wholesale tile is consistent throughout, double-check that the identification, specifications, and color numbers printed on the tile match those printed on the packaging box. Before making a purchase of floor tile tiles, double-check that the product certificate, trade mark, and quality inspection mark are all clearly visible.

Examine the technical specifications in their entirety before proceeding and make any necessary adjustments before moving forward.

When you find yourself in this situation, it is recommended that you use the fourth design pattern to solve the problem.

Before you begin installing your floor tiles wholesale tile patterns and designs, double-check that the colors used in the patterns and designs are distinct and consistent throughout the installation. Additionally, the manufacturing process should be flawless, with no visible color leakage, dislocated or broken lines, or inconsistent depth throughout the entire manufacturing process.

During the discussion, make a mental note of everything that is said and how it is said.

It takes several taps on the table's surface before the table is able to be moved from its fixed position. Many factors are taken into consideration when determining how crisp the sound will be, including the amount of porcelain that is used and the quality of the sound produced. If you use your left thumb, index finger, and middle finger to clip two corners together with your left index and middle fingers, hanging a ceramic tile should be a relatively simple process. By pressing down on the ceramic tile with your right index finger, you will cause the middle and lower portions of the ceramic tile to fracture, allowing you to see through the tile. A clear and pleasant sound, according to the majority of people's perceptions; the worst sound is dull and stagnant, resulting in the lowest possible quality in terms of both volume and sound quality.

It is possible to determine the infiltration rate of a ceramic tile by applying a small amount of water to the back of the floor tiles wholesale tile and watching it for a couple of minutes after the kitchen wall tiles wholesale tile has been dispersed. Increased density ceramic tiles are generally slower to absorb water, whereas lower density ceramic tiles are generally faster to absorb water and have a higher internal quality than higher density ceramic tiles. Higher density ceramic tiles are also more expensive than lower density ceramic tiles.

As a growing company, one of the most difficult challenges you will face will be the inability to obtain packaging on short notice when you need it. Standard boxes are a popular choice among businesses all over the world due to the fact that they are inexpensive and straightforward to obtain. Standard packages, on the other hand, may be effective in the short term, but they are not financially viable in the long run.

Additional warehouse space is required in order to accommodate oversize packaging. Aside from that, you take up additional empty space during delivery, which may necessitate the shipment of only air in some situations. As an example, consider the fact that this isn't a particularly cost-effective solution. Product packaging that is both customized and space-saving should be used for the primary packaging of your product. That can be accomplished in several ways.

Alternately, you could purchase a box that is custom-made for your product and ship it directly to your clients. When you use custom insert packaging, you get a package that is tailored to your product, almost as if it were a second skin for your products. This eliminates the need for void fill and allows you to ship your product with a lower dimensional weight than previously possible.

It saves time and money when custom insert packaging is used instead of standard insert packaging because void filling is no longer required. This reduces the amount of time and money spent on packaging when there is a large amount of empty space available.

Read More:How to Select the Most Appropriate Custom Product Packaging.

Packaging that is customized for your company can also be used as a powerful marketing tool to attract new customers. The use of digital printing will make it simple for you to brand your product packaging when it comes to marketing your product. Additionally, because it is significantly faster than traditional printing methods, it allows you to build stronger relationships with your customers.

The importance of the quality component should be highlighted at all times, and this should be a top priority. Despite the fact that you will want to save money wherever you can on your packaging and product shipping, it is still important to maintain a professional appearance and to represent your company in a favorable light. Select higher-quality packaging components and products over lower-quality alternatives whenever possible, and avoid settling for lower-quality packaging tools solely on the basis of price savings.

Keep in mind that when customers walk into your store, the first thing they will notice is the packaging you have chosen for them. In business, as in life, first impressions are lasting impressions, and this is especially true for businesses that conduct their entire operation online. Create an excellent first impression with customers is critical, and higher-quality packaging components are an excellent way to achieve this goal.

You will face many challenges as a growing company, one of the most difficult of which will be the inability to obtain packaging on short notice when you require it. A common choice among businesses all over the world, standard boxes are popular due to the fact that they are both inexpensive and simple to obtain. On the other hand, standard packages may be effective in the short term but are not financially viable in the long term.

It is necessary to have additional warehouse space in order to accommodate oversize packaging needs. Aside from that, you occupy additional empty space during delivery, which in some cases may necessitate the shipment of only air in certain circumstances. Consider the fact that this isn't a particularly cost-effective solution, as an illustration of the point. The primary packaging of your product should be made up of product packaging that is both customized and space-saving at the same time. There are several approaches that can be used to accomplish this.

Instead, you could order a box that is specifically designed for your product and ship it directly to your customers. In the case of custom insert packaging, you will receive a package that has been tailored to your product, almost as if the package were a second skin for your goods. Due to the elimination of void fill, you will be able to ship your product at a lower dimensional weight than was previously possible.

Read More:How to Select the Most Appropriate Custom Product Packaging.

Because void filling is no longer required when custom insert packaging is used instead of standard insert packaging, it saves both time and money when custom insert packaging is used. When there is a large amount of empty space available, this reduces the amount of time and money spent on packaging.

In addition to being a powerful marketing tool to attract new customers, customized packaging can also be used to promote your company. It also allows you to develop stronger customer relationships because it is significantly faster than conventional printing methods.

Throughout the process, it is critical to emphasize the importance of the quality component, which should be given top priority. However, despite the fact that you will want to save money wherever possible on your packaging and product shipping, it is still important to maintain a professional appearance and to portray your company in a positive light. Higher-quality packaging components and products should be preferred over lower-quality alternatives whenever possible, and lower-quality packaging tools should not be chosen simply because they are cheaper.

It's important to remember that when customers walk into your store, the first thing they'll notice is the packaging you've chosen to put them in. When it comes to business, as in life, first impressions are critical, and this is especially true for businesses that conduct their entire operation online, such as online retailers. It is critical to make a positive first impression on customers, and higher-quality packaging components are an excellent way to accomplish this goal.

What if I told you that you had never heard of the Metal Plating process before? Would you believe me? Would you believe me if I told you? This section of the course will teach you how to effectively implement design tactics in order to ensure that your final product has the greatest possible manufacturability. It is critical to optimize the design of your component in order to reap the greatest possible benefit from the die casting mould process and, as a result, to realize the greatest possible return on your die casting aluminum process investment. When designing a component for manufacture, keep in mind how it will be assembled in the factory and how it will be tested. As a result, you can be confident that your project is well-suited for die casting processes such as conventional die casting, multi-slide zinc castings, or injected metal assembly, among other possibilities. In other words, engineers should approach each project with the goal of designing it to be as manufacturable as possible from the very beginning, rather than the opposite.

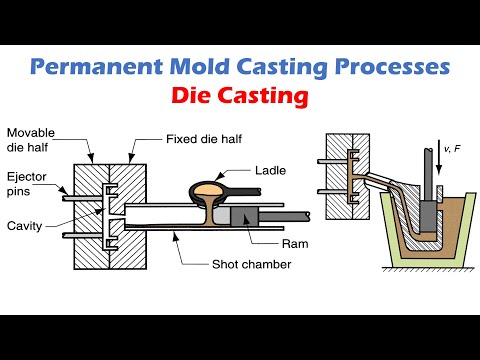

Die Casting - Permanent Mold Casting Processes.

Design for manufacturing (DFM) is a fundamental methodology that ensures that die cast parts meet all of the specifications that are required in the manufacturing process. As a result, the number of secondary operations is reduced, and the reliability of the parts is improved as well. Given that these operations can account for as much as 80% of a component's total cost in some cases, it is critical to minimize the impact of these operations on the component's design process as much as possible. DFM is much more than just a theoretical concept in project management; it is also a practical tool that can be applied in the real world of project management. Prior to the start of a project's manufacturing phase, it is common practice to implement a cost-cutting and inefficiency-reduction strategy to reduce costs and improve efficiency. To help you maximize the return on your investment in a die cast component, we'll walk you through three different design approaches that you can use to create a die cast component from scratch.

The Die Casting Process Step By Step

When corrosion resistance and structural stability are important considerations, thin wall aluminum is an excellent material choice, as demonstrated by the following example:Corrosion-resistant aluminum is an excellent material for aerospace applications because of its high dimensional stability as well as its high hardness, as well as the fact that it is relatively light in comparison to other metals. When attempting to reduce wall thickness, it is critical to ensure that the final product is uniform in terms of both appearance and performance. This is especially true when attempting to reduce wall thickness. Based on their combined effects, it is predicted that the castings produced will be consistent, stable, and repeatable, making them well-suited for the manufacturing process under consideration.

In addition to variable flow pressures and non-uniform solidification caused by variations in wall thickness, there are a number of other factors that can contribute to porosity in a material. When it comes to die casting, our engineers at Dynacast have a variety of tricks up their sleeves that allow them to produce a net-shaped component while maintaining a consistent wall thickness throughout the process of casting. Our engineers will use cores to achieve greater uniformity in the thicker walls, while also including structural integrity ribs in the cores to ensure that the structural integrity of the component is not compromised in any way during the manufacturing process. When designing your component, it is important to consider the draft angles and tolerances that are achievable for the materials that will be used in your project in order to avoid delays caused by the need to redesign the component. Draft angles of less than 0.5o are typically achievable with zinc, whereas draft angles of more than 2o are typically achievable with aluminum.

Alternatively, you might think about approaching your design from a broader perspective than you have so far taken into consideration. If you know the non-critical dimensions of a component, it is possible to design tolerance zones that are less stringent than the critical dimensions of the component. With the use of tolerance zones in your design, you can both extend the life of your tool by reducing the number of exact geometries that wear down and plan the tolerance stack-up of your entire component, saving time and money. As a result of using this method, you can avoid machining and secondary operations whenever possible, allowing your design to take care of the majority of the heavy lifting and allowing your die casting process to run as efficiently as possible.

Keeping track of how many components are being manufactured at any given time is the essence of productivity monitoring. Production tracking is a term used in the manufacturing industry to describe this process.

It is the measurement of variables in a manufacturing process that occurs during the manufacturing of a product during its production that is known as process monitoring. Things like temperature, pressure, and hold time, to name a few examples, are among the parameters to consider.

If the machine is up and running and producing parts, or if the machine has been halted and is no longer producing parts, the statement is correct.

It is necessary to terminate an application if it is running at an abnormally slow or rapid pace (and as a result, something is wrong).

There are a variety of factors to consider, including the types of raw materials that were utilized and how much more will be required in the near future.

How much machine and labor time was spent on the production of the components? How many components were produced? What was the total number of components produced? What was the total number of individual componentsProduction Monitoring Service were created?

Failures or out of control processes are terms used to describe processes that have gone out of control or have failed.

Keeping track of the manufacturing process as it happens is essential when attempting to determine the root cause for production problems. Who or what is responsible for the part's excessive thinness in the first place? Do you believe that the amount of time allotted for filling the jars was sufficient for the task? Nobody was ever able to determine what caused the air bubbles to appear in the component. Were there any indications that the screw pressure was too low at the time of the crash? Possibly. Root cause analysis is a technique used by engineers to quickly identify areas where problems may have occurred during the parts manufacturing process. When engineers have knowledge of critical process variables at the time of production, they can quickly identify areas where problems may have occurred during the parts manufacturing process.

To give you an example, consider the following circumstance:This is the process of keeping track of the progress of a 10,000-item job that is being watched over, and this is the process of keeping track of the progress of that job. Consider the following scenario: a job requires the production of 6,000 parts, but it has not yet been completed; Production Monitoring notifies the supervisor that the manufacturing rate has slowed and the job will most likely be completed later than anticipated; and so on. When the supervisor checks his email, he receives a similar alert from the quality monitoring system, which has begun to reject one part out of every twenty for the first time around the same time the supervisor checks his email.

As a result of the information, the supervisor summons an engineer, who begins an investigation into the information gathered from the process monitoring system as a result of it. No matter how high the barrel temperature of the machines rises to unacceptably high levels, the fill pressure remains within the prescribed range. The supervisor and the engineer have come to the conclusion that the job should be stopped and re-started on a different piece of apparatus. When referring to the use of historical data to determine which machine will be the best fit to complete the task at hand, it is common practice in some circles to refer to this as Runs Best Data. Because he is fully aware there was no issue with the fill pressure, he advises production management that the problem was not with their tool, but rather with something further down the production line. He begins the transfer of the tool from one piece of equipment to another once he has given his approval for the tool to be used on a new piece of equipment. If you are working with the new equipment, you can have the job up and running in less than 30 minutes, and all parameters will operate in accordance with the job specifications.

The engineering team is currently reviewing the information that has been gathered so far in terms of production information, quality information, and process information. It is possible to determine when the barrel temperature exceeded 950 degrees, when the production rate slowed, and when the number of rejected parts increased with millisecond accuracy, and he can pinpoint these events to the millisecond. For the purposes of this particular instance, it has been determined the temperature of the barrel was to blame for the malfunction. In the course of a machine inspection, it was discovered Production Monitoring Service the barrel temperature controls had failed prematurely after 425,000 cycles of operation. This was discovered after 425,000 cycles of operation. The inspection criteria for barrel temperature control have also been reset to 400,000 cycles, which is the maximum number of cycles that can be performed on the machine at any given time, in addition to the repairs that have already been completed.

Maintaining the proper care and styling of your wig will help to extend its lifespan by up to a year or more. You should also avoid exposure to harsh environmental factors such as direct sunlight, wind, or freezing cold temperatures.

If you take good care of your substitute hair, Indian virgin hair extensions is possible that the benefits of using it will last for up to two years or longer. The following six tips will assist you in keeping your hair extensions looking great for a longer period of time if you wear your wigs on a regular basis (for example, every night of the week).

1: If you are wearing wigs during the day and at night, it is recommended that you use a different wig for each occasion. In order to prevent them from becoming thin and worn out more quickly, it is beneficial to use your wigs in an excessive manner. This will help to prevent them from becoming thin and worn out more quickly.

Not to mention a honest hair factory reviews that's simple to put on for work or school, as well as one that can be referred to as "my precious sleeping wig," which you can refer to as whatever you want.

For the best possible appearance, brushing your sleeping human hair wigs before you put it on at night, as well as when you first wake up the next morning, is also extremely important. Brushing your sleeping wig every night before you sleep is a very simple, but extremely important, step in maintaining the health of your wig. Maintaining the wig's condition requires special attention because tangles and frizz can cause it to become damaged if it is not properly removed from the scalp.

Therefore, if you don't brush your hair on a regular basis, it will become brittle and difficult to detangle when the occasion calls for it to. Regular brushing will provide you with the benefits of a longer wear time and more restful sleep at night if you keep your sleeping wig in good condition.

Washing and conditioning your sleeping wig once a week with the appropriate hair products for synthetic or human hair wigs, depending on your personal preference, is recommended by the vast majority of virgin hair lace closure weaves experts.

When washing your hair, it is critical to use a pre-wash brush to ensure that all loose hairs have been removed from your hair before doing so. When washing and conditioning your hairpiece, take care not to damage the thread construction of the hairpiece in order to avoid damaging the thread construction.

Following the washing and conditioning process, thoroughly wash the inside of the 's cap to remove any excess hair products that may have been used during the process. Your scalp's likelihood of becoming itchy is increased if you have chemical residue left on your hair and on your scalp from your shampoo and conditioner.

Preventing the cap from absorbing the natural oils produced by your scalp while you sleep can be accomplished by placing an ultra-fine and clean cotton liner under your sleeping before going to bed.

Its primary function, aside from providing additional comfort while sleeping, is to prevent oil from building up within the wig's cap while the wig is being worn.

If there is an accumulation of oil in the cap, it is possible that the hair knots will become tangled or fall out. It is important to note that this can happen if there is an accumulation of oil in the cap, which should be avoided.

According to some estimates, between 10 and 50% of a home's energy loss occurs through its windows and doors, with 90% of the energy lost through windows being lost through the glass itself (see Figure 1). A significant amount of energy is being wasted by a small portion of your home's structural integrity, and this is unquestionably a significant amount of energy. It wasn't until 1975 that the first low-emissivity glazing solution was introduced to the market in an attempt to remedy the situation.

In most cases, thermal energy is the primary focus of attention when describing a surface's emissivity, which is defined as the amount of energy emitted at specific wavelengths by a surface at specific temperatures. To distinguish between perfect reflectors and perfect absorbers, a material is assigned a numerical thermal emissivity value ranging from 0 to 1, with the perfect reflector having an emissivity of zero and the perfect absorber having an emissivity of one. Emissionsivity is measured in units of 0 and 1. A perfect reflector has an emissivity of 0 and a perfect absorber has an emissivity of 1.

Metals, such as silver and aluminum, have thermal emissivities of less than 0.05, whereas standard clear glass has an emissivity of approximately 0.9, making it one of the highest emissivity materials available on the market. Instead, standard glass has a thermal emissivity of 0.9, which means that it allows 90% of the thermal energy to pass through it while reflecting the remaining 10% back into space. This has led to the conclusion that window glass requires assistance in reflecting heat back into the house.

When it comes to low e insulated glass, it makes sense to use it. A micron-sized, transparent coating is applied to the surface of clear glass, which is more effective at reflecting heat than the glass itself, resulting in a composition with lower thermal conductivity than regular glass. A low-E coating on glass keeps your home warmer by reflecting a greater proportion of the heat back into your home, and it can also keep you cooler by reflecting solar thermal energy from the outside world back into your home.